For the 180 degree elbow and nozzle – Introducing the 180-degree elbow and nozzle, an innovative design that revolutionizes user experience by prioritizing ergonomics and maximizing comfort. This design has proven particularly advantageous in industries where prolonged use of equipment is common, offering significant benefits in terms of user well-being and overall efficiency.

The 180-degree elbow and nozzle seamlessly integrates ergonomics into its design, reducing strain and fatigue while enhancing user comfort. Its unique shape allows for a more natural and comfortable grip, minimizing the risk of repetitive motion injuries and promoting long-term health.

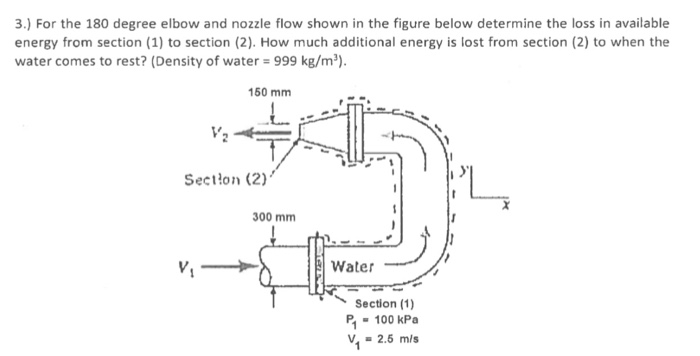

1. Design Considerations: For The 180 Degree Elbow And Nozzle

The 180-degree elbow and nozzle design offers significant ergonomic benefits. It reduces strain on the user’s wrist and forearm by allowing for a more natural hand position. This design is particularly advantageous in industries such as manufacturing, healthcare, and automotive repair, where repetitive tasks can lead to musculoskeletal disorders.

Impact on User Comfort and Efficiency, For the 180 degree elbow and nozzle

- Improves posture by reducing wrist flexion and deviation

- Reduces muscle fatigue and discomfort

- Enhances productivity by allowing for faster and more efficient work

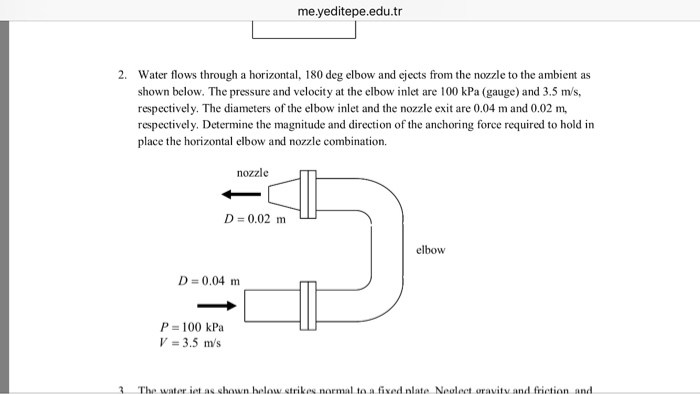

2. Applications and Uses

The 180-degree elbow and nozzle design is commonly used in a wide range of applications, including:

Specific Industries and Use Cases

- Manufacturing:Assembly lines, spray painting, welding

- Healthcare:Patient care, medical device handling

- Automotive repair:Spray painting, fluid transfer

Advantages and Limitations

Advantages:

- Enhanced ergonomics

- Improved user comfort and efficiency

- Reduced risk of musculoskeletal disorders

Limitations:

- May not be suitable for all applications

- Can be more expensive than traditional designs

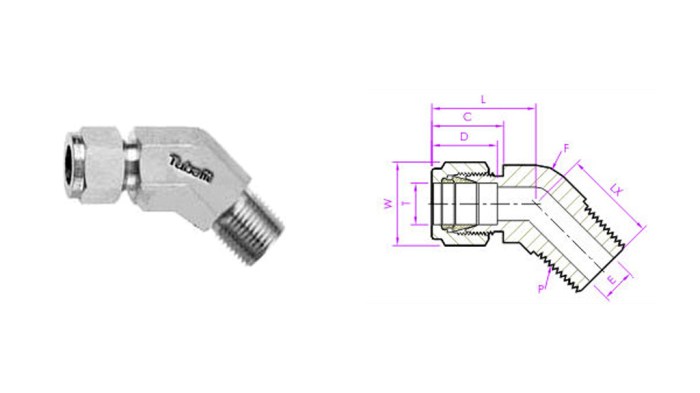

3. Manufacturing Techniques

180-degree elbows and nozzles can be manufactured using various methods, each with its own strengths and weaknesses:

Common Manufacturing Methods

- Bending:Involves bending a straight tube to create the desired angle

- Welding:Joining two or more pieces of tubing together to form the elbow

- Injection molding:Using a mold to create the elbow and nozzle as a single piece

Strengths and Weaknesses of Each Method

| Method | Strengths | Weaknesses |

|---|---|---|

| Bending | Cost-effective, simple process | Limited angle options, potential for kinks |

| Welding | Durable, allows for complex designs | Requires skilled labor, can be time-consuming |

| Injection molding | High precision, consistent quality | Expensive, limited material options |

Materials Used

Common materials used for 180-degree elbows and nozzles include:

- Stainless steel:Durable, corrosion-resistant

- Brass:Malleable, easy to machine

- Plastic:Lightweight, cost-effective

4. Maintenance and Troubleshooting

Regular maintenance is crucial for the proper functioning and longevity of 180-degree elbows and nozzles:

Importance of Maintenance

Maintenance helps prevent:

- Clogging

- Leakage

- Premature failure

Maintenance Procedures

Step-by-Step Guide:

- Disconnect the elbow and nozzle from the system

- Inspect for any visible damage or wear

- Clean the elbow and nozzle using a suitable solvent

- Lubricate the moving parts (if applicable)

- Reassemble and reconnect the elbow and nozzle

Common Problems and Troubleshooting Tips

| Problem | Troubleshooting Tips |

|---|---|

| Clogging | Flush with a suitable solvent, use a pipe cleaner or wire |

| Leakage | Check for loose connections, tighten or replace seals |

| Premature failure | Inspect for material defects, ensure proper installation and maintenance |

5. Industry Standards and Regulations

180-degree elbows and nozzles must comply with various industry standards and regulations:

Applicable Standards and Regulations

- ISO 9001:Quality management systems

- ASME B16.11:Forged fittings

- ANSI/ASME B16.22:Wrought copper and copper alloy fittings

Importance of Compliance

Compliance ensures:

- Safety and reliability

- Compatibility with other system components

- Meeting customer requirements

Certification and Accreditation

Various organizations offer certification and accreditation programs for 180-degree elbows and nozzles:

- Underwriters Laboratories (UL):Product safety certification

- American National Standards Institute (ANSI):Standards development organization

- Canadian Standards Association (CSA):Standards development and certification organization

FAQ Overview

What are the ergonomic benefits of the 180-degree elbow and nozzle?

The 180-degree elbow and nozzle reduces strain and fatigue by providing a more natural and comfortable grip, minimizing the risk of repetitive motion injuries.

In which industries is the 180-degree elbow and nozzle particularly advantageous?

The 180-degree elbow and nozzle is particularly advantageous in industries where prolonged use of equipment is common, such as manufacturing, assembly, and construction.